Transverse

Pilot line for wafer-scale micro-transfer printing

Micro-Transfer Printing

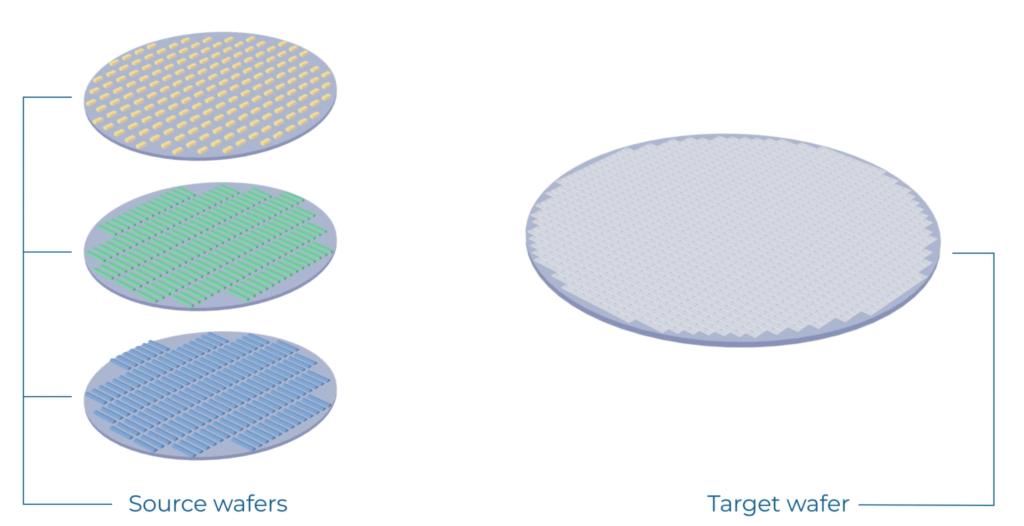

Micro-Transfer Printing enables the precise, mass transfer of various components (e.g. lasers, modulators, photodetectors). The ability to integrate diverse materials and components with high alignment precision make it ideal for heterogeneous integration.

Pilot line

The pilot line provides a platform for partners to evaluate and develop wafer scale micro-transfer printing processes (200mm) for their products. The expertise of imec and Ghent University in heterogeneous integration supports development-on-demand and prototyping.

Proven Experience and Expertise

Imec and UGent have a proven track record of heterogeneous integration through Micro-Transfer Printing. The pilot line is supported by this research expertise and is therefore placed at the forefront of Micro-Transfer Printing development.

Efficient and versatile

The wide range of possible components and materials that can be transferred onto various substrates make Micro -Transfer Printing a highly versatile integration method. Micro-Transfer Printing selectively transfers only the required devices or components and thereby optimizes the use of expensive source materials.

Latest News

-

INTERREG LIGHTUP – Call for Partners – SOAs Meet ISIPP: A New Step in Photonic Integration

-

Partnership announcement: Transverse partners with Albis Optoelectronics to advance micro-transfer printing of photodiodes

-

Transverse @ ECOC 2025

-

Kick-off seminar at PIC International

-

Meet us @ Photonics West 2025!

-

Launch website and LinkedIn

Our Services

-

Platform augmentation

Using micro-transfer printing, we are developing micro-transfer printing based processes to expand the capabilities of silicon photonics platforms—such as Imec photonics—by integrating advanced components like modulators, optical amplifiers, and lasers.

-

Prototyping

Innovation through rapid prototyping enables to quickly test, refine and optimize designs and process flows. Our non-commercial prototyping capabilities are supported by an R&D license from X-Celeprint for micro-transfer printing.

-

Development on Demand

Through Development on Demand projects in close collaboration with partners we ensure flexible and tailored solutions for process- and device development.

-

Supply Chain Development

Through close R&D collaboration with partners across the micro-transfer printing ecosystem—including pure-play foundries, source providers, and target platform developers—we are advancing technologies to establish an efficient, scalable supply chain and enable volume production.

Platform and Material Diversity

Versatility is inherent to Micro Transfer-Printing (MTP). MTP enables the integration of a diverse range of materials/components (e.g. III-V semiconductors, lithium niobate) on a large variety of platforms (e.g. silicon, silicon nitride, Lithium Niobate, …)

From high-performance optical components to electronic chiplets, MTP supports a wide range of applications. Our publications showcase only a part of the technology’s capabilities, highlighting innovations in photonics, electronics, and beyond.

Publications

-

Micro-Transfer Printed Continuous-Wave and Mode-Locked Laser Integration at 800 nm on a Silicon Nitride Platform

M. Kiewiet, et al., Laser Photonics Rev (2025). https://doi.org/10.1002/lpor.202500956

-

Compact low-voltage lithium niobate racetrack modulator on a silicon nitride platform through micro-transfer printing

Lisa De Jaeger et al., Optics Letters, doi:10.1364/OL.561544

-

Micro-transfer-printed short-wave infrared InP-on-silicon tunable laser

Xin Guo et al., Optics Letters, doi.org/10.1364/OL.549540, (2025)

-

Centimetre-scale micro-transfer printing toenable heterogeneous integration of thin filmlithium niobate with silicon photonics

Margot Niels et al, Opt. Mater. Express 15, doi.org/10.1364/OME.551748, (2025)

-

A High-speed heterogenous lithium tantalate silicon photonics platform

M. Niels et al, arxiv, doi.org/10.48550/arXiv.2503.10557

-

Heterogeneous integration of a High-Speed Lithium Niobate Modulator on Silicon Nitride using Micro-Transfer Printing

T. Vanackere, et al.. APL Photonics https://doi.org/10.1063/5.0150878 (2023)

-

Present and future of micro-transfer printing for heterogeneous photonic integrated circuits

Gunther Roelkens et al. APL Photonics . https://doi.org/10.1063/5.0181099 (2024)

-

Integrated Resonant Electro‐Optic Comb Enabled by Platform‐Agnostic Laser Integration

I. Luntadila Lufungula et al. , Lasers & Photonics Reviews, doi:10.1002/lpor.202400205 (2024)

-

III-V-on-Si3N4 widely tunable narrow-linewidth laser based on micro-transfer printing

B. Pan, et al., Photonics Research, 11(12), doi:10.1364PRJ.530925 (2024)